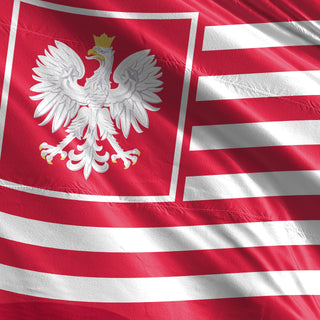

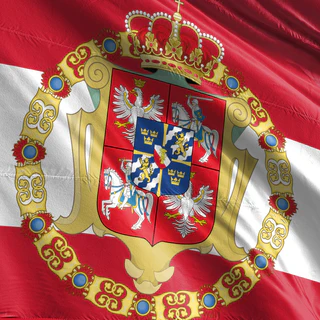

Step #1 - Designing your flag

Before we can print any custom flag, we need to design it of course. At Flagmaker & Print, we provide a free flagmaking app that works in-browser to help you prepare your design. FMP is, in fact, a custom form of online image editing software like Google Drawings. You can use it to import any files from your computer, and combine them to create your own personalized flag design.

Once you are happy with your design, press the 'Print My Flag' button to proceed to the printing and proofing stage. Here, the app will show you a preview of your flag while it prepares a print-ready version for our team. Internally, this process is often referred to as 'baking' the file.

Step #2 - Preparing transfer foil

Once you order, the prepared printfile is automatically sent to one of FMP's many worldwide suppliers. We often negotiate contracts with different suppliers, meaning two FMP flags may come from different sources depending on your location.

In the factory, your flag is created by using a technique called heat transfer sublimation. This is a process where heat and pressure transfer dye into the fabric. The design is first printed onto a special transfer paper using sublimation ink. Then, the paper is placed against the polyester fabric and subjected to high heat (typically 350–420°F (175–215°C)) and pressure using a heat press or calender machine. The heat turns the ink into a gas, which bonds with the polyester fibers, creating a vibrant, long-lasting image that won’t crack or fade easily.

If you've ever used an 'iron-on' shirt graphic, this is pretty much the same, but at an industrial scale!

Step #3 - Cutting and plotting

After printing, the polyester sheet is cut into the flag's final shape using laser cutters or rotary blade cutters for precision. Laser cutting is common because it simultaneously seals the edges, preventing fraying. For rectangular flags, this is straightforward, but custom shapes require programmed cutting patterns.

At Flagmaker & Print, we offer a 3:5 ratio as our standard cutting programme. However, we also offer a wide variety of custom shapes and modifications free of charge to all users. If you would like to have a custom shape, or modifications like tassles, make sure to order a 'Let Us Design Your Flag' product, our stand-in for a custom product trajectory.

Step #4 - Sowing and packing

Finally, grommets (metal eyelets) are added to the hoist side using a grommet press. The flag's reinforced edges—sometimes with a canvas header for added strength—is punched with holes, and metal grommets are pressed in to secure them. This ensures the flag can be attached to poles or halyards without tearing.

Once your flag is ready, it is handed off to our packing teams. The flag receives one final quality check, and is wrapped in a secure bag for transport. Luckily, flags are easy to ship and durable - as they fold into a nice package that can easily fit into most package post boxes.

Shipping times: Because we are a custom flag manufacturer, FMP flags take longer to arrive than ready-made objects. For custom flags, please allow for a delivery time of 3-4 weeks from the date of ordering.

Once you've ordered, keep an eye on your mailbox! You will receive a message once your flag has finished manufacturing, and when it is ready to ship.